| Subject | Hyundai Heavy rolls out zero-carbon ammonia duel-fuel engine | ||

|---|---|---|---|

| Reg. date | 2024-10-11 | Views | 1386 |

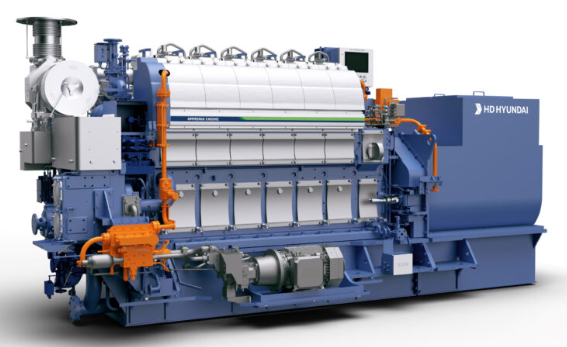

[Offshore Energy/October 10, 2024] South Korean shipbuilder HD Hyundai Heavy Industries has completed the model-based class approval testing for the ‘HiMSEN’ ammonia dual-fuel engine at its Engine Technology Center in Ulsan.

According to the shipbuilder, this is the ‘first’ ammonia engine in the world, applied with a high-pressure ammonia direct injection method.

The testing was attended by representatives from seven classification societies including ABS, DNV, LR, BV, RINA, ClassNK, and KR.

The South Korean company intends to start commercializing the HiMSEN ammonia engine shortly as the detailed examination and compliance review has been finalized with the model-based class approval.

The ammonia engine developed by HD Hyundai Heavy Industries is said to be suitable not only for ammonia carriers, but also for marine power generation and propulsion purposes. The company also plans to supply the engine to land-based power generation markets.

Until now, ammonia engines were based on a “low-pressure premixed combustion method” which burns a mixture of ammonia and air, which has been provided to the engine combustion chamber, through compression. The newly developed “high-pressure direct injection method” compresses air in the engine combustion chamber and then burns it by injecting ammonia with high pressure.

Despite its benefits of having great output and fuel efficiency, along with the mitigation of greenhouse gases such as nitrogen dioxide (N2O), engine companies around the world had difficulty developing this method due to its high technological complexity. While setting up an optimized fuel spraying time and period to maximize burning rate, HD Hyundai Heavy Industries also utilized the selective catalytic reduction (SCR) system to minimize the amount of nitrogen oxide and unburned ammonia.

In addition, the Integrated scrubber developed independently by HD Korea Shipbuilding & Offshore Engineering (HD KSOE) has been widely applied resulting in a drastic reduction of ammonia concentrations.

“The development of this ammonia engine has great meaning as it will be an opportunity for us to lead the market while providing an expanded eco-friendly duel-duel engine lineup,” an official of HD Hyundai Heavy Industries said.

“We aim to enhance our advanced technology and take the lead in the future eco-friendly ship market.”

Earlier this year, HD Hyundai Mipo, an affiliate of HD Hyundai Heavy, developed an ammonia-powered ship using a number of domestic technologies. The recently developed standard ammonia dual-fuel propulsion ship can transport 45,000 cubic meters of liquefied petroleum gas, ammonia, or vinyl chloride monomer (VCM).

HOME

HOME